Comprehensive Solutions for Surgical Suture Manufacturing

As part of our expanding portfolio, we are proud to offer end-to-end services in the design and development of high end suture manufacturing facilities. Leveraging our extensive expertise in the healthcare sector, we specialize in providing all the essential devices and systems required to produce high-quality surgical sutures, ensuring precision, efficiency, and compliance with global standards.

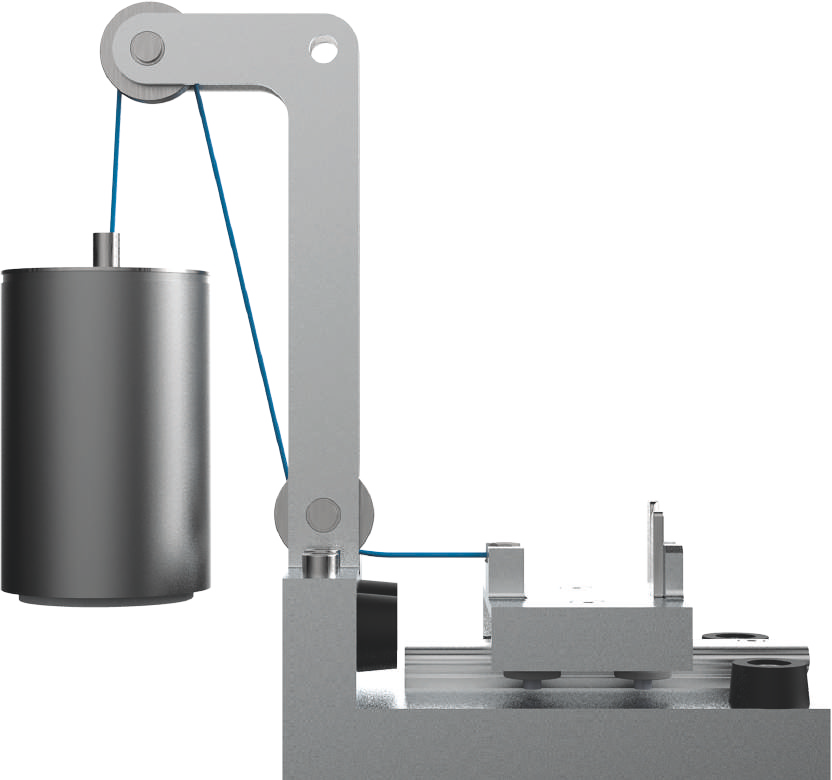

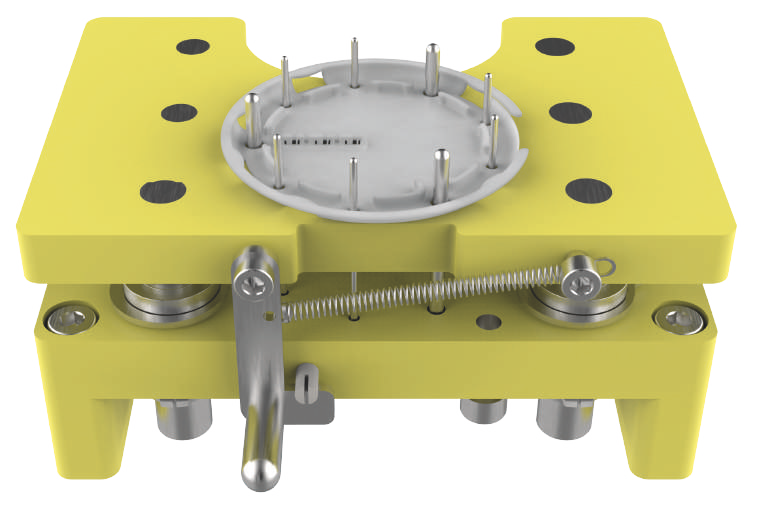

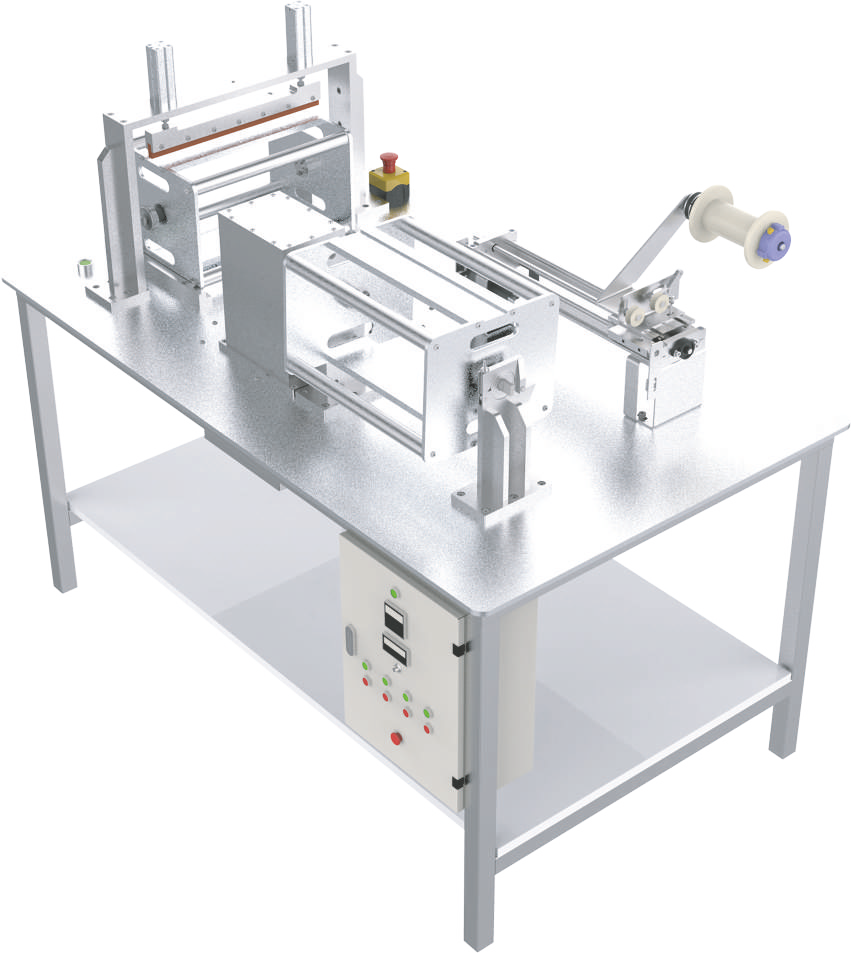

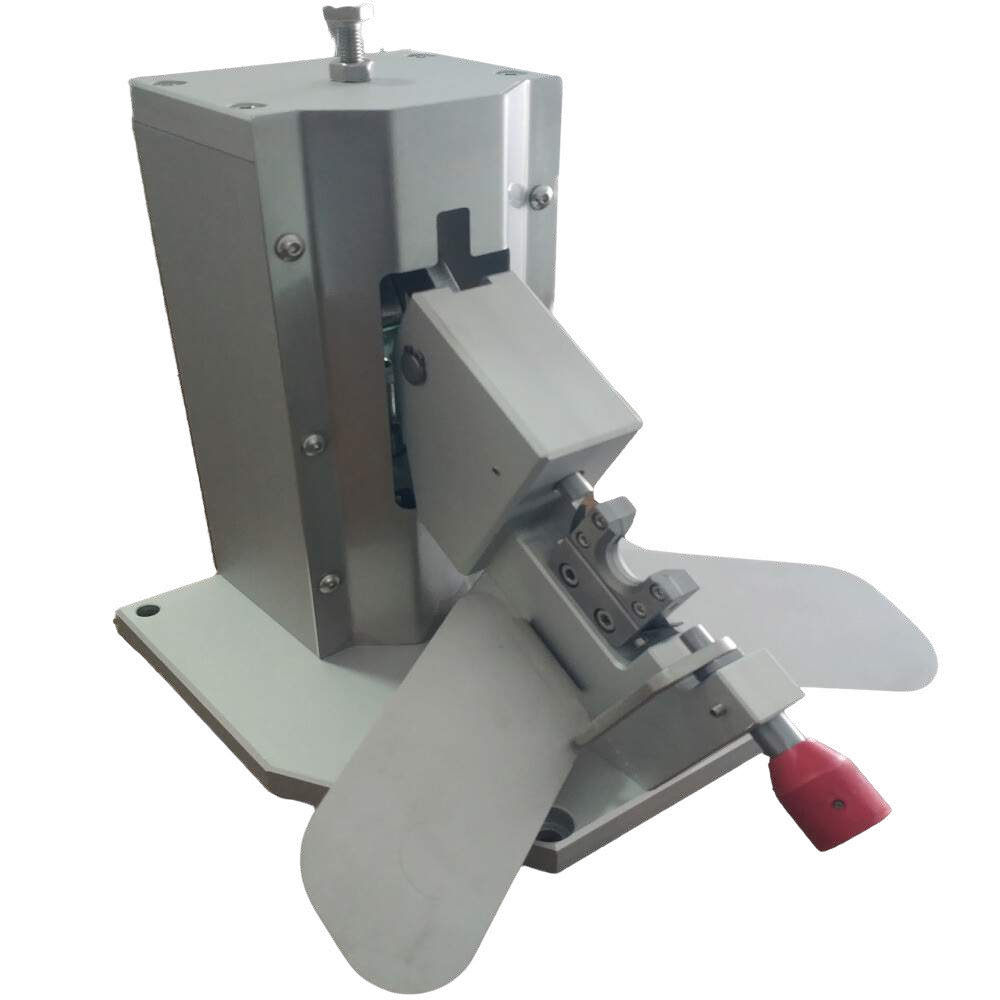

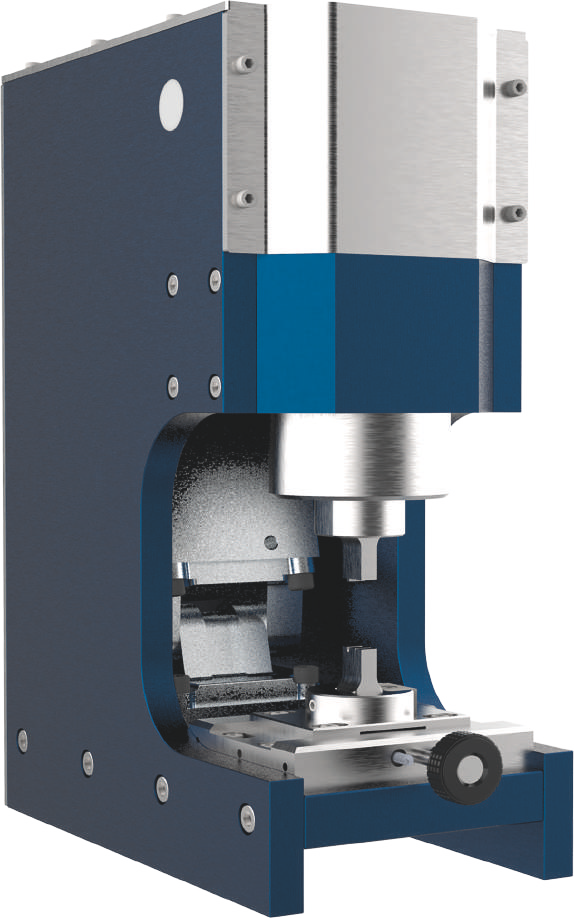

Our comprehensive solutions cover every aspect of suture production, from facility design to the delivery of advanced machinery. We provide equipment including Clean Rooms for controlled environments, Suture Winding Machines for precision handling, Needle Attaching Units for secure needle attachment, and Braiding Machines for durable suture construction. Additionally, we supply critical support devices such as Glove Boxes, Dry Cabinets, and Packaging Equipment to maintain sterility and ensure the integrity of the final product.

At HEDONE USA, we are committed to partnering with manufacturers to create efficient, reliable, and scalable suture production operations that meet the highest standards of quality and safety. Whether you're looking to establish a new facility or enhance your current capabilities, our solutions are designed to help you achieve your goals in the global healthcare market.

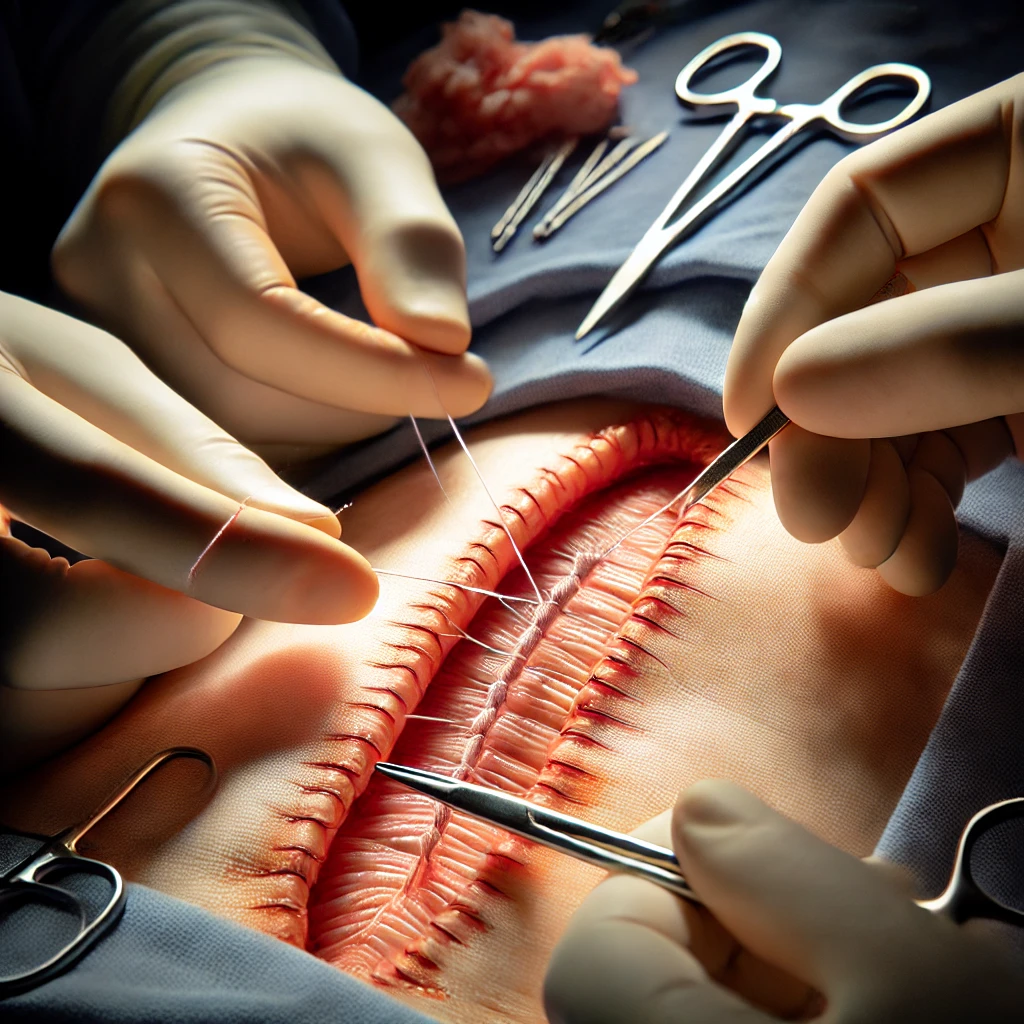

Surgical sutures are medical devices used to close wounds or surgical incisions, available in absorbable and non-absorbable types. Absorbable sutures are designed to break down naturally in the body over time, eliminating the need for removal. Common types include Polyglycolic Acid (PGA), Polylactic Acid (PLA), and Catgut, which are used in tissues that heal rapidly. Non-absorbable sutures, made from materials like Nylon (NY), Polypropylene (PP), or Silk (S), remain intact in the body unless manually removed and are used in areas requiring long-term tensile strength. Specialty types include Polyglactin 910 (Vicryl), Polydioxanone (PDS), and Polyethylene Terephthalate (PET) for specific surgical needs. Each type of suture material is selected based on its biocompatibility, tensile strength, and application-specific requirements, ensuring optimal wound closure and healing.

Compatible Surgical Sutures: PGA(W/O needle)- PGLA(W/O needle)- PGAR(W/O needle)- PGLAR(W/O needle) - PGCL – PDO -PP – PA –SILK (W/O needle) - UHMWPE Machinable Surgical Sutures Diameter and Lenght (USP – cm): USP 6/0 - 5/0 - 4/0 - 3/0 - 2/0 - 0 - 1 - 2 - 3 - 4 - 5 - 6 - 7 45 - 50 - 60 - 75 - 90 - 100 - 120 - 150 cm (Any Custom size can be added) Production Capacity: 3600 pieces/hour

Key Features:

The most important features expected from surgical needles are that they maintain their sharpness during the surgical operation and that the lubricating coating on it preserves its properties throughout the ongoing procedures. During each stitching application, the losses in the sharpness of the needle and the lubricant coating affect the penetration performance and cause undesirable results during the operation. An ideal needle is expected to maintain its performance for at least 10 stitches.