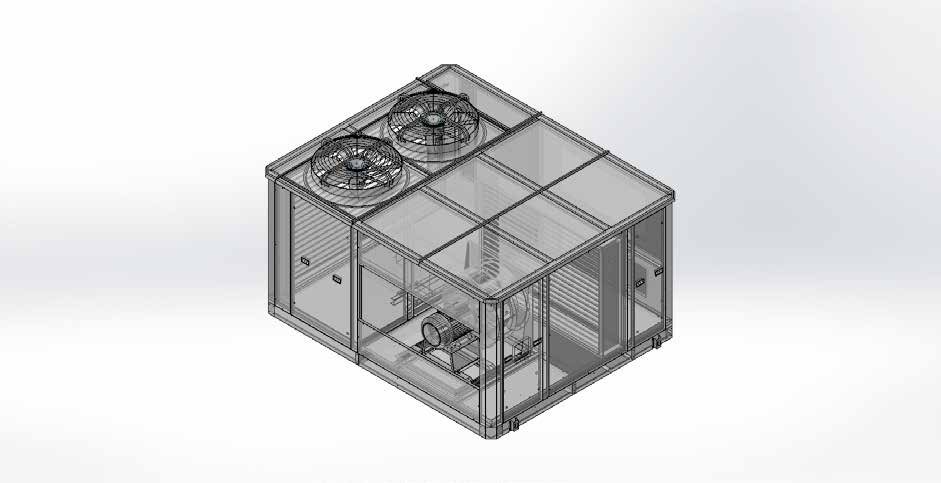

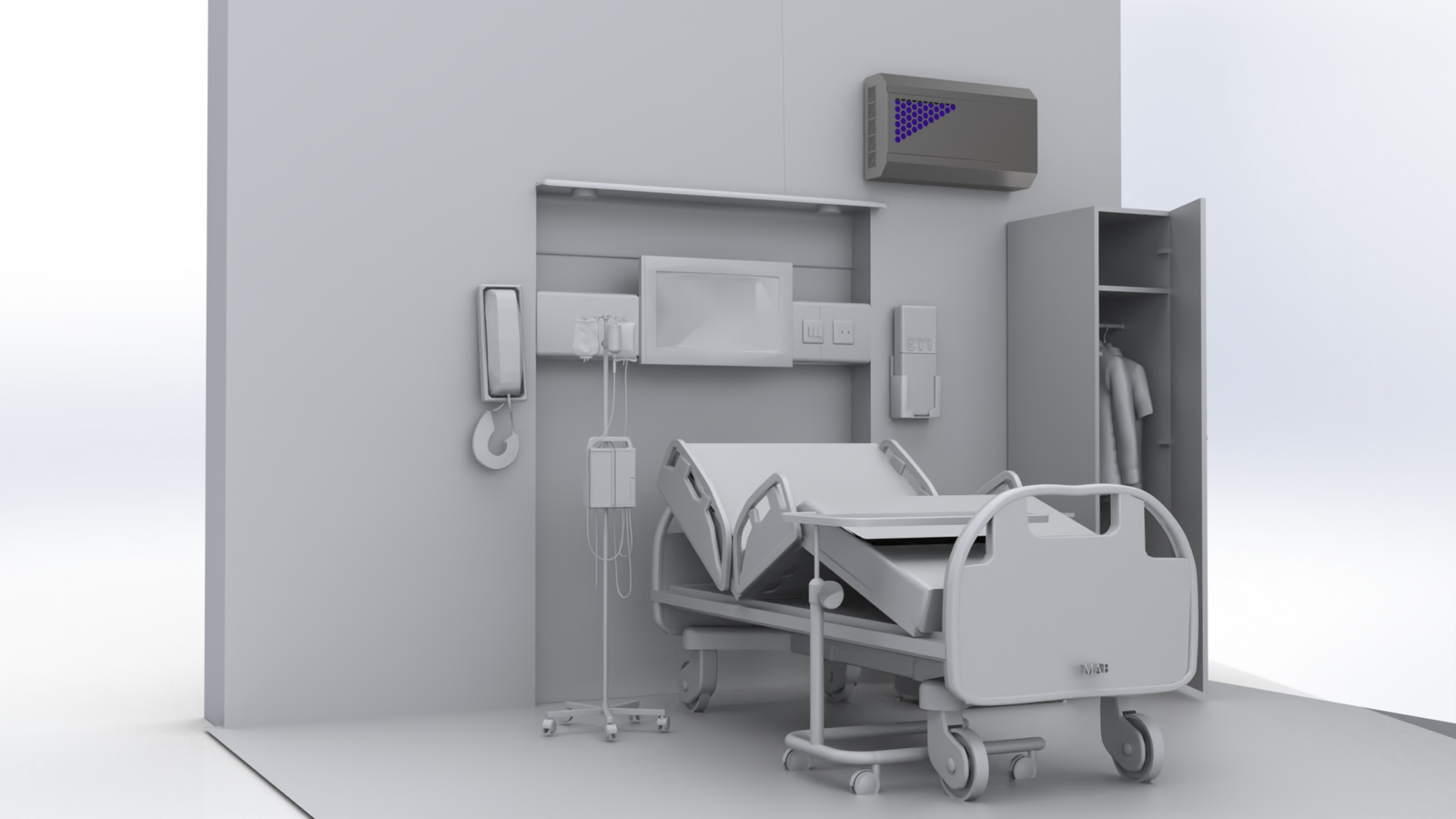

Ductwork

Ductwork is a critical component in the air handling systems of hospitals, serving as the network through which air is distributed, conditioned, and returned. It ensures efficient airflow, maintaining the desired environmental conditions in various hospital areas such as operating rooms, intensive care units, and patient wards. Ductwork plays a key role in maintaining clean, filtered air, reducing airborne contaminants, and controlling temperature and humidity levels.

Key Technical Specifications for Ductwork:

Material: Galvanized steel, aluminum, or stainless steel, depending on hospital standards and requirements.

Insulation: Internal or external insulation with thermal resistance (R-value) to minimize heat loss and prevent condensation, typically using fiberglass or foam materials.

Air Leakage Class: Certified to low-leakage standards, usually in compliance with Class A or B ductwork leakage specifications.

Pressure Rating: Ductwork is designed to handle both positive and negative pressure environments, typically rated between 250-2000 Pa.

Size and Dimensions: Customizable according to the hospital layout and airflow requirements, adhering to SMACNA or DW144 duct construction standards.

Fire Resistance: Complies with fire safety regulations, including fire-rated coatings or fire damper integrations.

Noise Control: Integrated sound dampening features to reduce noise transmission, essential for hospital environments.